The test bench allows for testing of various types of hydraulic dampers used in rail vehicles.

A characteristic curve is obtained that shows the dependency between the damping force on the shock absorber stroke.

FEATURES

- Load force acting axially on the tested damper,

- Ensures required forces and speeds of the damper,

- Stroke speed adjustment,

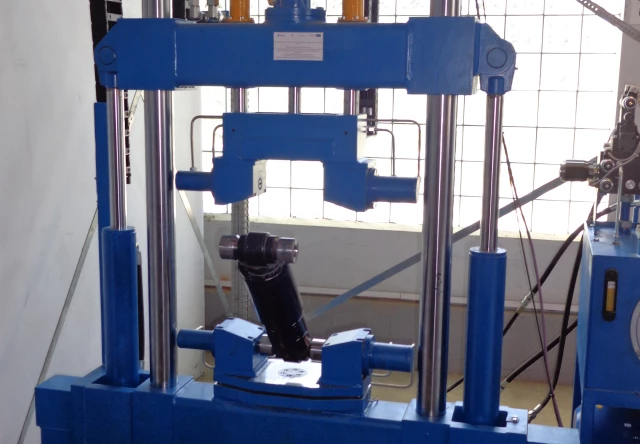

- Adjustment of the damper to a position corresponding with rail vehicle operating conditions by means of an angular pivoting mechanism,

- Electronic control of the testing process,

- Test is fully automated,

- Measurement data are recorded, archived and can be printed out,

- Temperature compensation (operating environment simulation).

TEST BENCH COMPONENTS

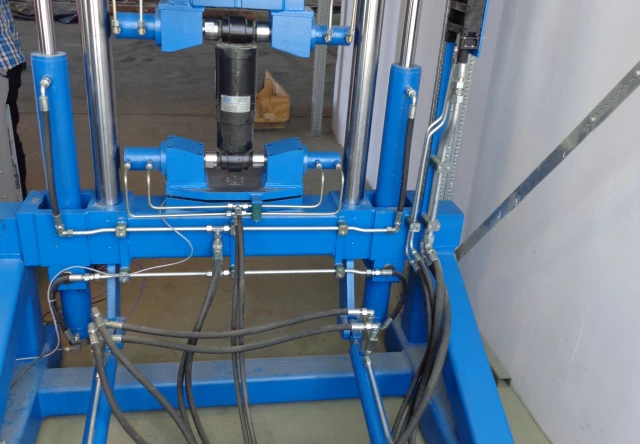

- Rigid mechanical structure,

- Mounting clamps that do not require damper rubber components to be dismantled,

- Servomotor drives responsible for pivoting and test of a damper

- Electrical cabinet built into the device structure,

- PLC controller, computer with database.

- Angle adjustment range: up to 90°

- Min. damper length: 200 mm

- Max. damper length: 1200 mm

- Working stroke: 300, 350 mm

- Maximum test force: 30 kN

- Maximum speed (adjustable): 0 - 0,3 m/s

- Maximum acceleration: 20 m/s²

- Accuracy of measured stroke: ± 2%